At the heart of the electric vehicle is the battery. And just as the demise of the earliest electric cars has been attributed to the primitive state of battery technology in the early 20th century, it will likely be battery technology that will, once again, make or break the electric vehicle in the 21st.

Range anxiety is, as academic studies have shown, a real thing. This is the trepidation people feel about their EV’s battery running flat in the middle of nowhere, potentially far from a charging station. Even as EV battery sizes increase and EVs overall become more efficient, the fear of running out of charge could still be a considerable impediment to consumer adoption.

Tackling this concern requires manufacturers to offer EVs capable of driving long distances without having to recharge. As GM’s Vinod Kumar explains in a related story in this series, that means better batteries. EV batteries have to perform a balancing act and are an amalgamation of compromises. For example, they must be large enough to contain enough of a charge to power the car for hundreds of miles, but not so large that their size and weight makes the vehicle impossibly cumbersome or heavy. They must possess sufficient power density to make them both powerful and efficient, but not so much that they become unstable. They must be able to charge quickly, yet maintain a steady temperature and not degrade over repeated charge cycles.

Most EVs today rely on some variation of the lithium-ion battery, in which lithium ions move from a negative electrode to a positive electrode during discharge and in the opposite direction when charging. Lithium-ion batteries first became commercially available in the 1980s, but their capacity and performance have been increasing ever since, through a continuous process of refinement by corporations and by academic researchers.

But EV batteries as we know them could be poised to experience a step-change in development; a breakthrough that could see a huge boost in efficiency while seeing costs plummet.

A new lithium-ion battery

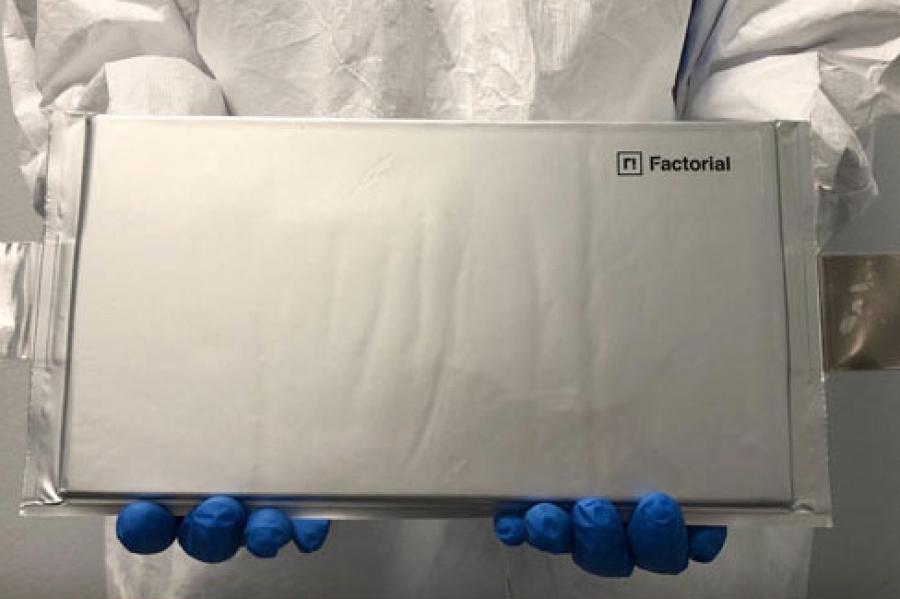

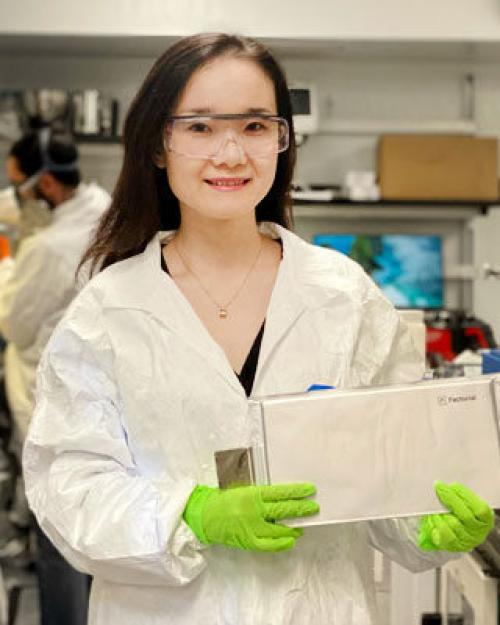

Step forward, Siyu Huang, MS ’11, PhD ’13, MBA ’14, founder and CEO of Factorial Energy, which develops solid-state batteries for EVs. In April this year, Factorial came out of stealth mode after some six or seven years of research and development of their first product, unveiling a 40-amp-hour solid-state battery cell.

Solid-state batteries contain a solid instead of a liquid electrolyte, giving them a much higher energy density than conventional lithium-ion batteries. Factorial says its cells have a 20 to 50 percent higher energy density than standard lithium-ion batteries, which translates directly to a 20 to 50 percent greater driving range.

“That provides mitigation for range anxiety,” Huang says. “I drive an electric vehicle too, so it’s always difficult when you’re driving in the wintertime—that range anxiety can be kind of brutal.”

Huang says that from an early age she was concerned with climate change and spent a lot of time thinking about how to tackle pollution. She studied chemistry at Uppsala University before attaining her PhD in chemistry at Cornell in 2012, before going on to found Lionano, a company focused on improving the components within lithium-ion batteries.

“I realized batteries were going to be a big thing because they were the technology that could change transportation and the clean-tech landscape in the near term,” Huang says.

She unveiled Factorial last year alongside co-founders Alex Yu, the company’s president, and Héctor D. Abruña, Emile M. Chamot Professor in the Department of Chemistry and Chemical Biology in Cornell University’s College of Arts and Sciences.

“One thing we have learned over the years is that, when it comes to batteries, it’s never about how great you are in one specific aspect,” Huang explains. “For example, you could have an extremely high energy density battery, but if it can only work for 10 charge cycles that won’t work for the electric vehicle market. A battery is all about compromises: that might make it less sexy, but you have to make it deliverable, commercializable and really practical to the market application.”

That’s why the much sought-after better battery has proved so elusive. Compared to advances in computing, battery development is a long, drawn-out process. Huang refers to Moore’s Law of technological development, based on Gordon Moore’s 1965 observation that the number of transistors on a microchip doubles every two years. “Moore’s Law for batteries takes about 20 years; that is, it takes about 20 years to double the energy capacity.”

A cheaper and safer battery

As well as greater range, higher energy density can translate into cheaper batteries, as a solid-state battery requires less material than a conventional lithium-ion unit with a similar capacity. Huang adds that Factorial’s battery doesn’t contain precious or rare-earth metals, making it easy to scale up the production process. Furthermore, the lion’s share of the production process for Factorial’s batteries requires equipment and utilities that are already in use for making lithium-ion batteries, keeping the costs of switching manufacturing processes to a minimum.

Factorial says its solid-state batteries are also safer. “The conventional electrolyte in your cell phone or your car typically has a flash point between 60 to 75 degrees Celsius,” Huang says. “Our solid-state electrolyte isn’t flammable until at least 200 degrees Celsius.” That higher ceiling also means manufacturers can eliminate certain thermal management systems currently needed for batteries, further lowering costs.

“We’re really excited to see the momentum building in this market,” Huang says. “We’re going to be a significant contributor to uptake [of solid-state batteries] in the industry, and we want to be future suppliers and manufacturers of batteries for automotive OEMs and their e-drive initiatives.” While the battery industry is currently dominated by a handful of big players, “there is a lot of potential to increase that,” Huang says. She doesn’t see one company dominating, but instead, “there’ll be multiple winners in the solid-state space over the next few years, much like with the Covid-19 vaccine.”

At the end of October, Factorial announced it would be partnering with Korean automaker Hyundai to test its solid-state batteries in Hyundai electric vehicles, marking the next step in bringing solid-state cells to market. It is Factorial’s first major strategic investment from a major carmaker. Speaking to the news, Huang said the move would “help unlock mass adoption of electric vehicles—and the resulting environmental benefits.”

Read the story on the SC Johnson College of Business website.