As the need to find climate change solutions becomes ever more urgent, Cornell chemists are leading the way with innovative and far-reaching discoveries, including better electric batteries, carbon capture technologies, renewable plastics and improvements in solar cells.

“We firmly believe that chemistry has the potential to help solve many of the world's problems. At Cornell, we're working on those solutions,” says Geoffrey Coates, the Tisch University Professor in the Department of Chemistry and Chemical Biology in the College of Arts and Sciences (A&S).

“I remain deeply optimistic that the technology, the science that we can discover, will lead to long term viable solutions,” says Andrew Musser, assistant professor of chemistry.

The College’s chemistry department is well known for its sustainability-related research and its faculty have been recognized with numerous awards, from a Macarthur “Genius Grant” to the Enrico Fermi Award.

Not only does this research help to attract ground-breaking faculty, but it also brings in graduate students and postdoctoral fellows with similar interests. Klarman Fellow Alexandra Easley said the department’s strength in multiple areas, including sustainable polymers, carbon dioxide capture and batteries, sold her on Cornell. “To get all of that in a single department is not common,” she says.

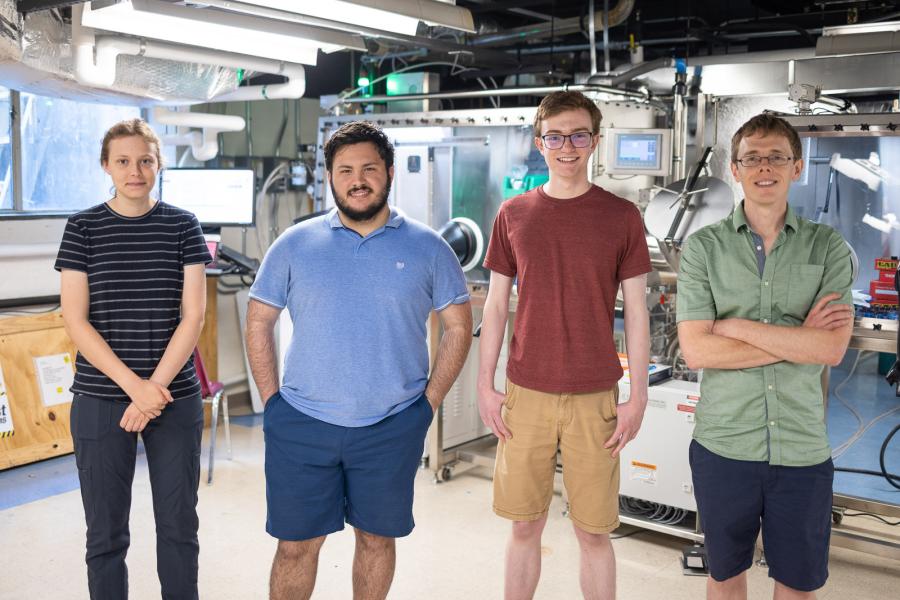

Add in the collaborative nature of the department and access to Cornell’s facilities across campus — including the Cornell Center for Material Research, the Cornell NanoScale Science and Technology Facility and the Cornell High Energy Synchrotron Source (CHESS) — and scientists say they have the ideal environment for breaking new ground.

“What really sets our department apart from many others out there is it's very multidisciplinary, very collaborative,” says Phillip Milner, associate professor of chemistry. “You have a lot of people crossing traditional lines of chemistry. And I think that really opens up some interesting opportunities and thinking about different ways to tackle problems.”

“Scientifically, Cornell offers just world-class facilities and the infrastructure for energy material research and also for doing important research for climate change,” says Yao Yang Ph.D. ’21, assistant professor of chemistry.

Carbon Capture

With atmospheric carbon dioxide (CO2) levels rising at an alarming rate, the need to reduce these levels is critical, but current carbon capture and storage techniques require too much energy to be useful. So, Cornell chemists have figured out a way to use sunlight as the energy input, making it efficient and sustainable.

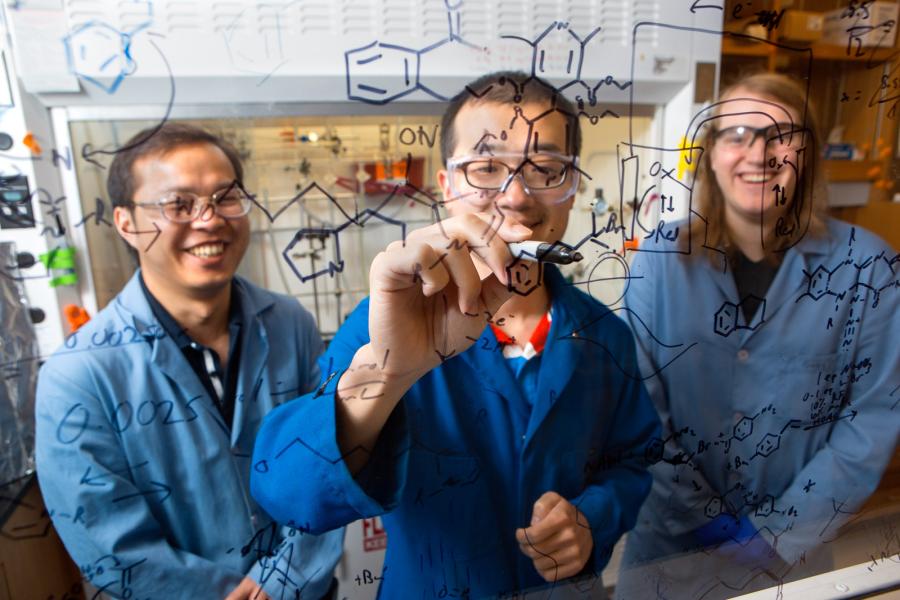

The research team, which includes Milner; Brett Fors, the Frank and Robert Laughlin Professor of Chemistry; Tristan Lambert, the William T. Miller Professor of Chemistry and department chair; and numerous graduate students, has been supported by the Cornell Atkinson Center for Sustainability and by the State of New York, through the New York State Energy Research and Development Authority (NYSERDA). Other research on carbon capture in the Milner group is supported by the National Science Foundation and the U.S. Department of Energy Office of Basic Energy Sciences.

The researchers have explored numerous other carbon capture solutions, including using sugar, low-cost alkali metal salts and electrified charcoal as “sponges” to soak up carbon.

“We've identified these super stable, super cheap, everything you pretty much could want in carbon capture molecules,” says Milner. “There's engineering challenges when you try to bring it up to the large scale, but it all comes back to chemistry.”

Yang also works on carbon capture, using electrochemistry to manipulate the electrons of molecules, doing chemistry at the nanometer scale.

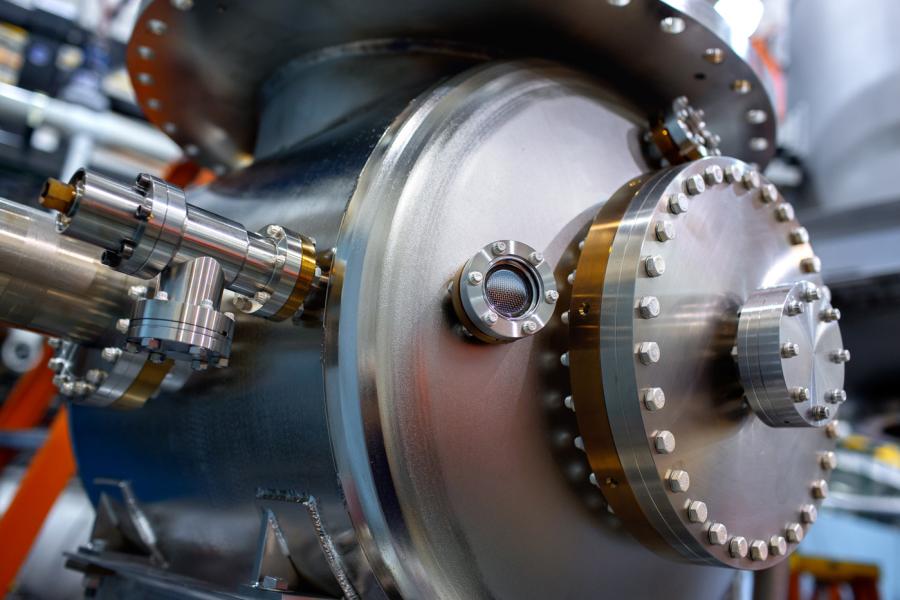

“We are developing some first-of-their-kind techniques, based on an electron microscope dedicated to liquid electrochemistry, which can probe the chemical reactions for carbon dioxide reduction,” says Yang, who uses transmission electron microscopy as well as the synchrotron X-ray at CHESS — one of only five high-energy synchrotron facilities in the world and the only synchrotron in the U.S. operated on a university campus.

Yang and Erik Thiede, assistant professor of chemistry, have received an Atkinson Center Fast Grant to develop machine learning algorithms to uncover hidden features of catalysts that drive carbon dioxide reduction reactions.

A new project, funded by the Atkinson Center, will establish a carbon capture testing station at the Cornell natural gas power plant to support the development of new carbon capture technologies. The testing station will be available for use by Cornell researchers as well as those from industry and elsewhere.

“It will allow people to test their catalyst and carbon capture materials on actual flue gas. This is very difficult to do in the private sector,” says Milner, who leads the project along with faculty from Cornell Engineering.

Having captured all that CO2, however, the next question is what to do with it. One idea: use it to make polymers (plastics are polymers).

Polymers and recycling

“Plastics are a really amazing class of materials that provide functions that no other class of materials can come close to. Wrappings keep our food safe, plastic lenses in our glasses let us see and N95 masks are made out of polypropylene,” Coates says. “If you didn't have plastics, your car would be a lot heavier, fuel economy would be worse and it wouldn't be as safe. I don't think there's any question that plastics are a class of materials that we can't get rid of, but they unfortunately do have a lot of negative impacts.”

Much plastic is single-use; only a tiny percentage of what’s put into recycling bins actually gets recycled, and most of that is recycled into a lower grade.

Making a pound of plastics generates about three pounds of carbon dioxide, an energy intensive process. Coates estimates the plastics industry generates about a gigaton of CO2 every year. And the environmental impact is enormous: about a third of plastic packaging ends up in the environment, mostly in the soil and ocean.

“There are even microplastics in the air we breathe,” says Coates.

Cornell’s strength in polymer chemistry goes back almost 100 years, to the 1940s and Nobel Laureate Paul Flory.

“He wrote a book that underpins pretty much all modern polymer chemistry while he was a professor here,” says Milner. The textbook, “Principles of Polymer Chemistry,” is still used today.

“Cornell is one of the top schools in the country for the expertise it has in polymer chemistry and with the faculty members it has,” Easley says.

Coates, for example, has been widely recognized with awards for his discovery of efficient synthetic processes to make important high-performance plastics from biorenewable resources, as well as finding innovative ways to improve recycling.

Fors has created an alternative to a non-recyclable plastic from a bio-sourced material that offers durability and malleability but can be easily recycled and degraded. In a collaboration with Robert DiStasio Jr., associate professor of chemistry and chemical biology (A&S), Coates and Fors have used machine learning to lessen the environmental impact of high-density polyethylene (HDPE), one of the world’s most commonly used plastics.

“If we can start recycling polymers so that we don't have to incinerate them to get some energy back, it could have a really big impact,” says Fors.

Much of the work on these sustainable polymers is funded by the National Science Foundation (NSF) and U.S. Department of Energy (DOE); Coates and Fors were both previously part of the NSF Center for Sustainable Polymers.

Solar cells

Research into solar technology is booming at Cornell in many departments, including chemistry, where scientists are working to create more sustainable solar cells.

“We're basically trying to enhance the efficiency of traditional solar cells by using purely organic materials,” says David Bain, a fifth-year doctoral candidate in Musser’s lab. “They're far more recyclable and easier to process, so less energy goes into making them, and also there's less waste.”

Musser’s research group, which each year includes students from the Nexus Scholar Program and other undergraduates, studies the interactions between light and matter in organic materials, with the goal of improving their properties.

“Most of the light that a solar cell absorbs turns into heat and that heat is wasted. A solar cell cannot provide more power than the percent of the light that it absorbs. We've had some important breakthroughs that let us capture some of that heat and turn it into another form that could be captured as more electricity,” says Musser.

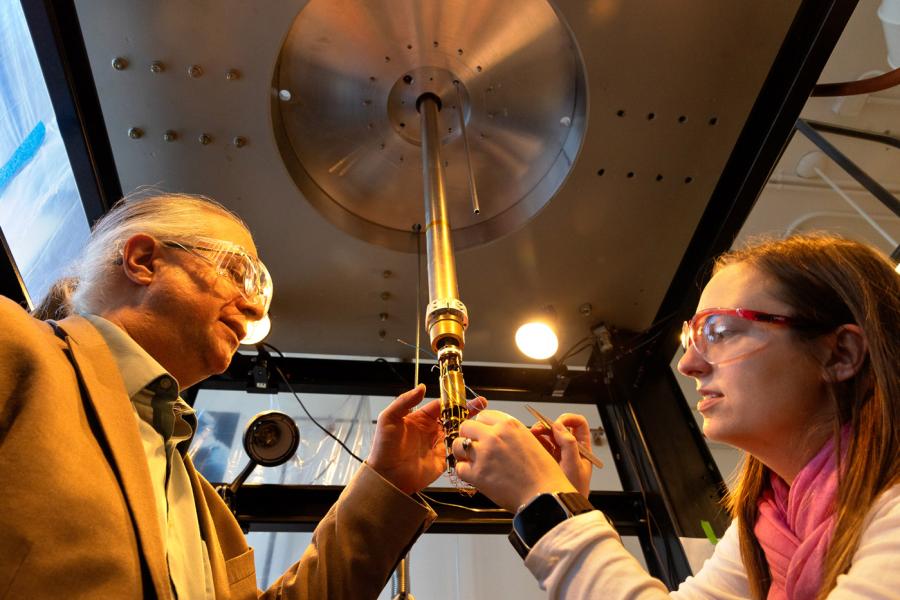

Taking a different angle, John Marohn, professor of chemistry and chemical biology, has been working with Lara Estroff, chair of the Department of Materials Science and Engineering in Cornell Engineering, to reliably grow durable perovskites – compound minerals that have become an alternative to silicon in solar cells — with optimal performance. As part of this effort, Marohn‘s team has invented a way to measure the longevity of electrical charge at the molecular scale, and they are applying this new technique to study both perovskite and all-organic solar cell films.

Green hydrogen, fuel cells and batteries

“One of the major contributors to climate is, of course, fossil fuel usage,” says Peng Chen, the Peter J. W. Debye Professor of chemistry. “To decrease fossil fuel usage, you want to find alternative energy sources. In our department, we’re developing better catalysts for fuel generation and energy conversion.”

One of these alternatives is “green” hydrogen. “Hydrogen is energetically dense, meaning per mass it provides a lot of energy compared to fossil fuels and you can utilize that hydrogen fuel by turning that into energy by using an anion exchange membrane fuel cell,” says Alexandra Macbeth M.S. ’20, Ph.D. '25, who worked in the Coates’ lab.

Current fuel cells and electrolyzers (which split water into hydrogen H2 and oxygen O2) use polymers to transport ions through the cell but are neither efficient nor durable. Cornell chemists are working on alternatives, such as anion exchange membranes, which enable the use of high performance and much lower cost catalyst materials for both fuel cells and electrolyzers.

“These membranes can also be used in batteries that are able to store energy on a grid scale, in water filtration, heavy metal extraction and drug recovery as well,” says Macbeth.

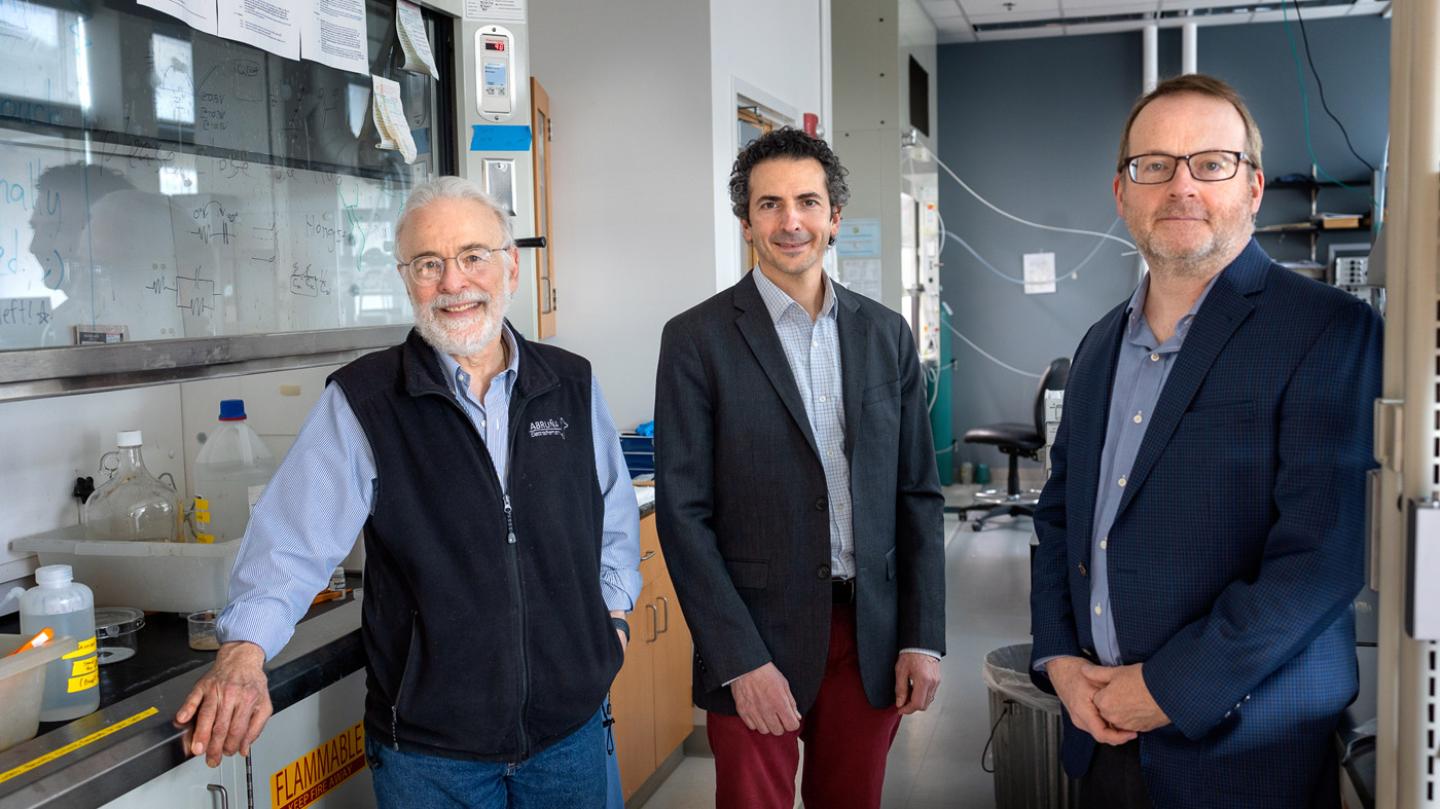

Much of the research on fuel cells and green hydrogen by Coates, Fors and Héctor D. Abruña, the Émile M. Chamot Professor of Chemistry, has been done through the Center for Alkaline Based Energy Solutions (CABES), an Energy Frontier Research Center funded by DOE. The work has also been supported by the 2030 Project: A Cornell Climate Initiative.

“And we do a lot of characterization for materials – fuel cells and batteries – at CHESS,” says Abruña, who serves as CABES director.

Cornell’s great strength in multidisciplinary collaborations has helped fuel many of the advances made by Cornell chemists: Abruña notes that CABES is about fifty-fifty A&S and Engineering faculty.

Abruña is well known as a leader in the use of electrochemistry, a critical tool for developing better batteries and fuel cells. He recently received both the $250,000 Dreyfus Prize and the Enrico Fermi Award, one of the oldest and most prestigious science and technology honors bestowed by the U.S. government.

One of Abruña’s projects has been transformative for the university: in March 2025, President Michael I. Kotlikoff cut the ribbon for a Level 3 electric vehicle fast-charging station and the first of its kind on Cornell’s campus as part of the Abruña Energy Initiative.

“Batteries with fast-charging capabilities are needed to meet the growing energy demands of modern technologies,” says Fors. He and the Abruña group have been able to synthesize polymeric battery materials that reach more than 90% charge in less than a minute.

Greenhouse gases

Cornell electrochemists are also creating technologies that help reduce energy usage in industrial applications and turn greenhouses gases into valuable compounds, such as pharmaceuticals.

Song Lin, Tisch University Professor (A&S), has pioneered a way to incorporate carbon dioxide into a series of organic molecules vital to pharmaceutical development. Lin received a Green Chemistry Challenge Award from the U.S. Environmental Protection Agency for his contributions to environmentally sustainable chemical development.

Coates, too, received a Green Chemistry Challenge Award, for his work making polymers using carbon monoxide and carbon dioxide.

Milner focuses on capture and functionalization of greenhouse gases. “How do we separate these dangerous, environmentally hazardous gases from emission sources? And then how do we turn them into valuable compounds?” he says. His lab has found a way to handle fluorinated gases as solids, a process that could someday be used to capture harmful fluorinated emissions and convert them to valuable drug-like molecules or agrochemicals.

To deal with greenhouse gases, though, scientists must first understand them. Kyle Lancaster, professor of chemistry, in collaboration with Abruña, has discovered a surprising source of nitrous oxide, a potent and long-lasting greenhouse gas.

Wastewater treatment

Droughts, a dire consequence of climate change, have made sources of useable water an urgent issue. Wastewater can be used for agriculture and other purposes, but removing micropollutants from wastewater has proved challenging and can be energy intensive. A team led by Chen has taken a novel approach, harnessing his technical specialty of single molecule, single particle imaging. This led his team to find a way to use semiconducting nanomaterials powered by sunlight to adsorb toxic chemicals on the materials’ surface and degrade them, a form of “photocatalysis.”

“We’re utilizing renewable green energy to drive chemical transformations,” Chen says.

In a collaboration with Milner’s group, Musser is also using light in innovative ways, designing new materials and making certain chemical conversions easier.

“Right now, the focus of this is on ways to degrade persistent pollutant molecules and make them less dangerous, turn them into new feedstocks,” Musser says. “This is a chemical recycling that also deactivates some really toxic stuff. But the same concept could be used to just take normal chemical syntheses and make them more energy efficient because they're driven by sunlight instead of a massive oven.”

Entrepreneurship

Many of the innovative research projects by faculty have been translated into real world solutions and successful companies.

Gabriel “Gaby” Rodríguez-Calero, M.S. ’12, Ph.D. ’14, and Kristina Hugar MS ’12, Ph.D. ’16 co-founded Ecolectro with Abruña and Coates, using technology that grew from their work with them during their graduate studies, creating membranes for low-cost alkaline exchange membrane electrolyzers, a process critical to green hydrogen production. Abruña and Coates serve as science advisors to the company.

Two other businesses have come from the Abruña lab: Conamix and Factorial Energy.

“At Conamix, which is based in Ithaca, they're commercializing lithium sulfur batteries that were developed in my group,” Abruña says.

Factorial Energy, based in Boston and recently profiled in the New York Times, began as a startup in Ithaca called Lionano. “They're doing exceptionally well – they have raised around $300 million in venture capital. They're doing solid state batteries,” says Abruña. “Mercedes-Benz will put out cars later this year with batteries coming from Factorial Energy.”

Another successful company, Novomer, was founded by Coates, Tony Eisenhut ’88, and Scott Allen, Ph.D. ’04 to apply research from Coates' lab to produce biodegradable plastics and other polymers from renewable sources and waste products, including carbon dioxide. The company founders won a national award for their development of innovative technologies that have benefited society and improved people’s lives.

Coates’ latest endeavor is a Cornell-Praxis startup called Intermix Performance Materials, with the goal of commercializing Coates’ research into making recycled polymers better than the original plastics.

But technological advances can only go so far, says Musser, unless human behavior and policies also change. “There are bigger societal issues that are going to determine whether the solutions Cornell researchers are developing can work,” he says.

Madhur Srivastava, assistant research professor of chemistry, addressed those issues by designing a way to help consumers track, and thereby moderate, their electricity use. He conducted a pilot study in collaboration with Avangrid, NYSEG’s parent company.

“We have no understanding of how much electricity each appliance uses, for example, or each light bulb, or how the costs change for a particular time of use,” says Srivastava. “How can we change our behavior if we have no analysis of it?”

Musser, too, thinks any chemistry-based solution has a major human component. “For me, it's really become about training the people. And I think that's where the big impact is going to be,” he says. “Because no one person, no one group is going to solve this, so we need to multiply our efforts wherever we can.”